Soundproofing is one of those topics where small decisions make an enormous difference. Choosing the wrong material can leave you with a wall that still leaks noise, a ceiling that lets footsteps echo endlessly, or a studio that simply cannot achieve the silence you need. At Sound Pro Solutions, we work with these problems every day, and one of the questions homeowners ask us most often is simple: what is mass-loaded vinyl and why does everyone in acoustics talk about it?

Mass-loaded vinyl, often abbreviated as MLV, has become one of the most effective and versatile soundproofing materials available today. It is powerful not because of some gimmick, but because of physics. When you add mass, you make it harder for sound waves to pass through a structure. MLV does exactly that while staying flexible, thin and easy to work with. If you're considering any acoustic upgrade in your home, office or studio, this material is worth understanding deeply.

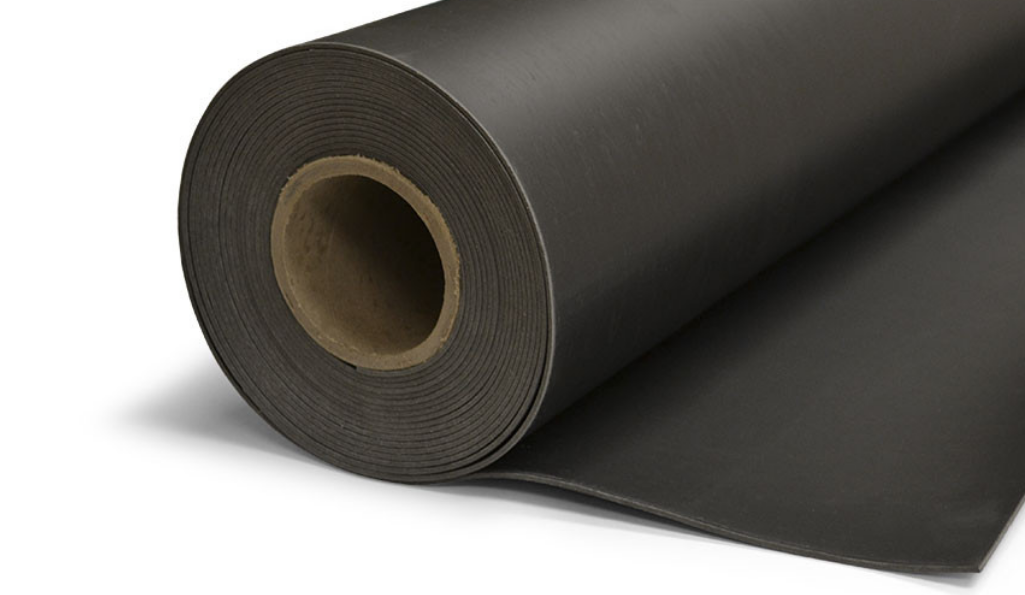

What Is MLV and Why It Matters for Soundproofing

Mass-loaded vinyl is a dense, flexible sound barrier designed to reduce the transmission of airborne noise. Many soundproofing products rely on thickness, layers or trapped air. MLV relies on mass. It increases the weight of a wall or ceiling without increasing its depth. This allows it to perform like a heavyweight material while remaining far easier to install. To put it simply, what is MLV? It's the modern alternative to old-school lead sheets, offering the same blocking power without the health risks or cumbersome handling.

We recommend MLV when someone needs a serious improvement without tearing down entire structures. This is especially helpful in apartments, offices and older homes where privacy and comfort matter but full demolition isn't an option. Its dense structure helps prevent voices, television sound, traffic noise and mechanical rumble from traveling from room to room. Because it remains flexible, it doesn't crack under pressure or seasonal shifts the way rigid boards sometimes do.

What Is Mass-Loaded Vinyl Made Of

Understanding the material composition is essential because density determines performance. Homeowners often assume soundproofing is about foam, "acoustic panels" or insulation alone, but real noise blocking requires mass. That's where MLV shines.

Key Materials and Density Ratings

A typical sheet of mass-loaded vinyl contains a blend of PVC (polyvinyl chloride) reinforced with heavy mineral fillers such as calcium carbonate or barium sulfate. These fillers dramatically increase density while allowing the material to remain flexible. This combination is precisely what gives MLV its impressive ability to stop airborne noise. When people ask what is mass-loaded vinyl made of, we explain that it's essentially a heavyweight polymer designed to behave like a soft, flexible sheet of metal. The added mass is what resists vibration, while the vinyl structure prevents cracking and keeps the sheet manageable during installation.

The density is usually measured in pounds per square foot. Common options include 0.5 lb/sq ft for moderate sound control and 1 lb/sq ft for aggressive noise blocking. Higher density means better performance, but also more weight, so it's important to select the right balance for your project.

Different Thicknesses and Their Applications

MLV is available in several thicknesses, most commonly ranging from 1/16 inch to 1/8 inch. Thicker material generally provides better sound attenuation but requires stronger fasteners and careful handling. For residential walls and ceilings, 1-pound material is the sweet spot. Studios, mechanical rooms or commercial spaces may require thicker options to combat stronger noise sources.

Thickness also affects how the material behaves during installation. Thinner sheets bend more easily around corners and pipes, while thicker sheets deliver better isolation for large flat surfaces. No matter the thickness, each version is engineered to add mass without excessive bulk, making it one of the few materials that combine heavy sound-blocking performance with manageable handling.

What Is Mass-Loaded Vinyl Used For

Because MLV is flexible and highly dense, it can be installed in places where rigid materials simply cannot fit. We often recommend it for complex acoustic issues, especially where lightweight construction allows noise to travel freely.

Its versatility is the reason professionals reach for it in residential, commercial and industrial settings. Some materials only shine in one category. MLV is different. It adapts. It wraps. It blocks. And it does all of it without requiring significant changes to your existing construction. That's why what is mass-loaded vinyl used for is a question with many answers.

Mass Loaded Vinyl for Walls

Walls are one of the most common applications because drywall alone simply doesn't contain enough mass to stop sound transmission. When installed behind new drywall or over existing surfaces, mass-loaded vinyl for walls acts as a dense sound barrier that significantly lowers noise transfer between rooms. It's especially useful in bedrooms, shared walls in multifamily units, home theaters and offices where privacy is essential. For homeowners who've tried insulation and still hear everything, MLV can provide the extra blocking power they're missing.

MLV Sound Deadening for Floors and Ceilings

Floors and ceilings often allow noise to pass quickly because they connect multiple rooms vertically. MLV can be installed under floating floors, beneath carpet padding or between ceiling joists. While it cannot replace structural isolation systems, it dramatically reduces airborne noise and helps tame mid-frequency disturbances such as conversation, television and light impact noise. In multi-story homes or apartment-style living, mlv sound deadening is one of the most effective ways to create a sense of separation and quiet.

Wrapping Pipes and HVAC Ducts

One of the most overlooked paths for noise is ductwork. Metal ducts carry sound like hollow tubes. Wrapping them in MLV adds mass where it matters and can significantly cut down on mechanical noise and cross-talk between rooms. The same applies to plumbing pipes, especially in bathrooms or multi-unit buildings where pipe noise can become a constant nuisance.

Vehicle and Equipment Soundproofing

MLV isn't limited to buildings. It's used extensively in automotive and equipment applications. When installed behind interior panels or inside engine compartments, it blocks road noise, engine vibrations and mechanical hum. For professionals working with industrial equipment, the material helps control machine noise at the source. This is where mass-loaded vinyl (mlv) demonstrates its flexibility as a high-performance sound barrier that adapts far beyond conventional construction.

Does Mass-Loaded Vinyl Work

This is one of the most common questions we receive from clients who are overwhelmed by conflicting advice online. Some people hear the word "vinyl" and assume it's something lightweight or decorative. Others confuse it with acoustic foam or insulation and expect it to solve issues it was never designed for. The truth is simple. MLV is one of the most effective ways to block airborne noise without adding significant bulk to a structure. But it must be installed correctly and used where its strengths matter. Homeowners who understand how this material works typically get outstanding results. Those who expect it to behave like magic foam usually don't.

How MLV Soundproofing Blocks Noise Transmission

To understand the science behind mlv soundproofing, think about how sound waves work. Airborne noise travels as vibration. When it hits a wall, the wall vibrates too. The more a wall vibrates, the more sound passes through to the other side. MLV reduces that vibration by adding a continuous sheet of heavy, flexible mass that resists movement. Unlike rigid boards, which can resonate, MLV dampens vibration because it moves differently from the structure behind it. It acts like a shock absorber, absorbing and slowing energy before it travels farther. When added to drywall or subfloors, this material disrupts the transmission path and increases the wall's ability to stop unwanted noise.

This is also why it's important not to stretch MLV too tightly during installation. The slight flexibility helps it perform better, letting it behave as both a damper and a barrier. It works exceptionally well in concert with other materials such as resilient channels, double-drywall assemblies or viscoelastic damping compounds.

STC Ratings and Real-World Performance

Sound Transmission Class (STC) ratings measure how well a wall or ceiling blocks airborne noise. Higher numbers mean better performance. A typical single-layer drywall wall sits around STC 33, which is why voices travel easily between rooms. When you add MLV between drywall layers, the wall can jump several STC points depending on the density and assembly. Many clients see improvements of 7-10 points, which is enough to make conversations far less audible and reduce TV or traffic noise significantly.

However, STC ratings don't tell the whole story. They focus mostly on mid and high frequencies. Real homes deal with bass, vibration and structure-borne sound too. That's why people often ask does mass-loaded vinyl work when the noise source feels deep or powerful. The answer is still yes, but expectations must be realistic. MLV excels at airborne noise like voices, barking dogs, TV audio and traffic hum. For heavy mechanical vibration or bass frequencies, it's only part of a larger system. Combined with proper sealing, insulation and decoupling, it becomes a crucial contributor to a high-performance assembly.

MLV vs Other Soundproofing Materials

Many homeowners wonder how MLV compares to materials like fiberglass insulation, acoustic foam or foam mats. The truth is that none of these materials do the same job. Each one serves a different acoustic purpose. Fiberglass insulation absorbs sound inside the cavity but doesn't block transmission. Acoustic foam improves room acoustics but barely stops noise from leaving the space. Foam mats may help with small vibrations but lack the density needed to block sound.

That's where MLV stands apart. Its density allows it to block sound, while its flexibility helps reduce vibration. When we explain this difference to clients searching for mlv sound deadening, the reaction is usually the same. They realize foam alone was never going to solve their problem. Mass is the foundation of soundproofing, and MLV provides exactly that without requiring a complete rebuild of the room.

Choosing the Right Mass-Loaded Vinyl for Your Project

Not all MLV is the same. Density, thickness and flexibility determine where each type performs best. Lighter versions work well in smaller residential projects or when adding mass to delicate structures. Heavier versions are ideal for studios, commercial offices or spaces exposed to loud outdoor noise. Because MLV adds weight to a structure, it's also important to consider the load-bearing limits of the installation area.

When clients ask us which version to buy, we start by identifying the type of noise they want to block. Speech leakage requires a different strategy than mechanical rumble or street noise. We also evaluate the structure itself. Some walls have enough strength to support 1 lb material. Others may need reinforcement.

Finally, we remind every customer to consider long-term plans. If you're already investing in mass, insulation upgrades or acoustic treatments, choosing mass-loaded vinyl that matches your project's scale ensures you get the most out of your effort. As always, we help clients navigate these decisions and recommend products that arrive quickly thanks to our streamlined shipping process and clear return policy.

Recent posts